Failure of a Circulation Pump Seal Could Lead to a Catastrophic Leak

Author:admin Date:2023-06-02

Using a mechanical seal to control the process pressure inside a MIC storage tank can be a serious concern. Typically, the mechanical seal is designed to handle the full process pressure in the event of a failure. However, if it fails, it could potentially allow large volumes of rapidly expanding superheated steam to escape. In the case of the MIC storage tank, the failure could have catastrophic consequences.

During the commissioning phase, an issue was observed which could be a precursor to a catastrophic leak. The circulating pump seal was found to be defective. After the commissioning phase, a leak occurred which caused numerous workers to suffer serious inhalation injuries. The leak was not the first time the mechanical seal had failed; it had also happened many times in the past. This time it was more serious. The leak covered a large area and blew apart after only two days of continuous operation.

After the commissioning phase, the factory supervisors could not prove that a deliberate act of sabotage had occurred. However, the factory's response to the circulating pump seal failures was inconsistent with the warning signs of an impending disaster. In addition, the community came to expect leaks and unexplained smells from the factory.

A recurring maintenance problem developed at a fossil fuel generation plant in southern California. In addition, the sealing solution used by the plant was not up to par. It used a single mechanical seal and had a poor thermal efficiency. It also required extensive water usage. These issues led to higher maintenance costs and reduced factory production.

After a fatal incident in which a worker was injured, the factory's workers' union asked for changes in design and control of repeat process releases. They wanted the MIC circulation pump seal to use a ceramic, fouling-resistant mechanical seal. This seal was installed in the next MIC circulation pump.

However, the MIC circulation pump seal was found to be defective. After a catastrophic leak occurred, the MIC circulation pumps were shut down. The factory's supervisors could not prove that a deliberate sabotage had occurred, but they did think that the MIC could be a hazard. They also did not believe that the leak could be repaired. The leak was a disaster for the community, but it was not the fault of the workers' union.

The failure of the mechanical seal could have caused a leak within the storage tank. This would have caused the tank mixture to become unstable, which could result in the need for a pressure relief system. The leak was also considered to be the most logical cause of the circulation pump seal failure.

A better process containment solution was adopted. A pressure control valve was installed to equalize the pressure differential acting on the mechanical seal faces. The PCV also allowed the system operator to monitor the seal's health. In addition, a pressure transducer was installed to measure the mechanical seal's performance. The system was also enhanced with a magnetic separator and level switches.

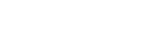

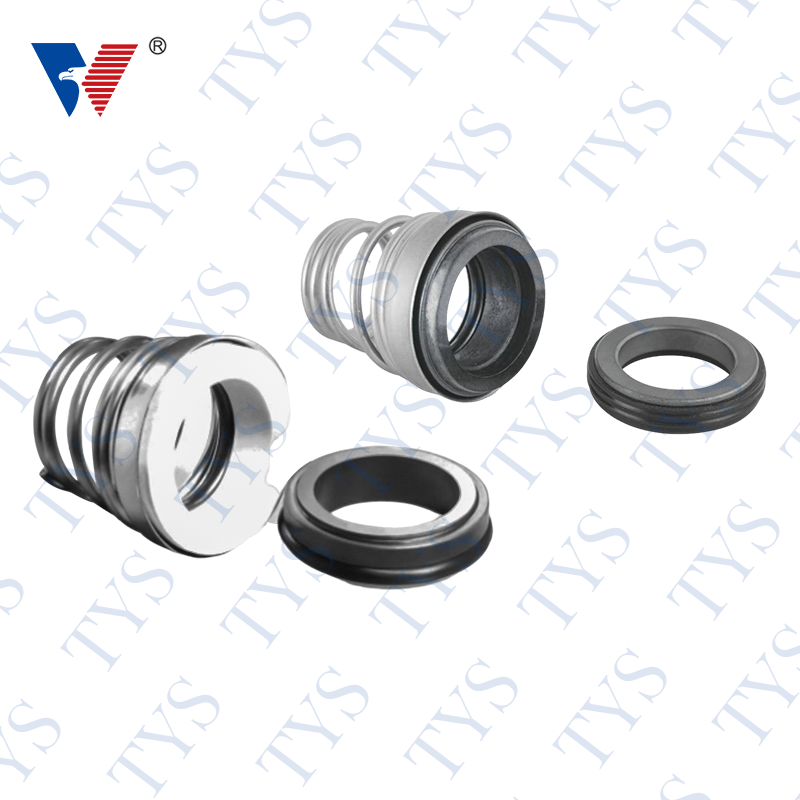

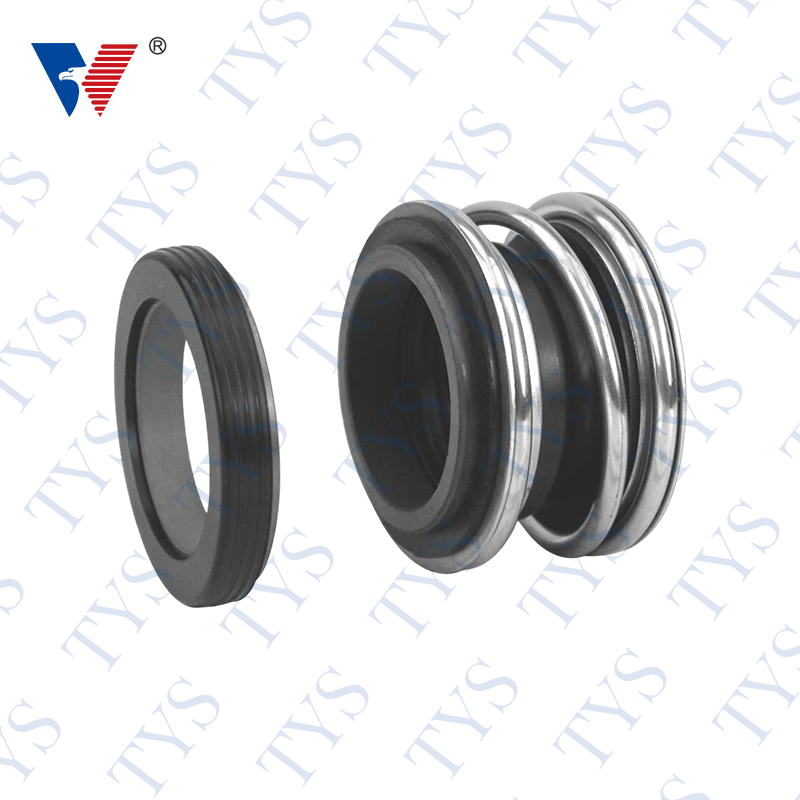

TYS 155 Single spring mechanical seals for water pump seal

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)