It is important to choose one that can withstand a variety of different conditions

Author:admin Date:2023-06-16

Choosing a Vertical Pump Seal

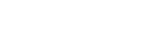

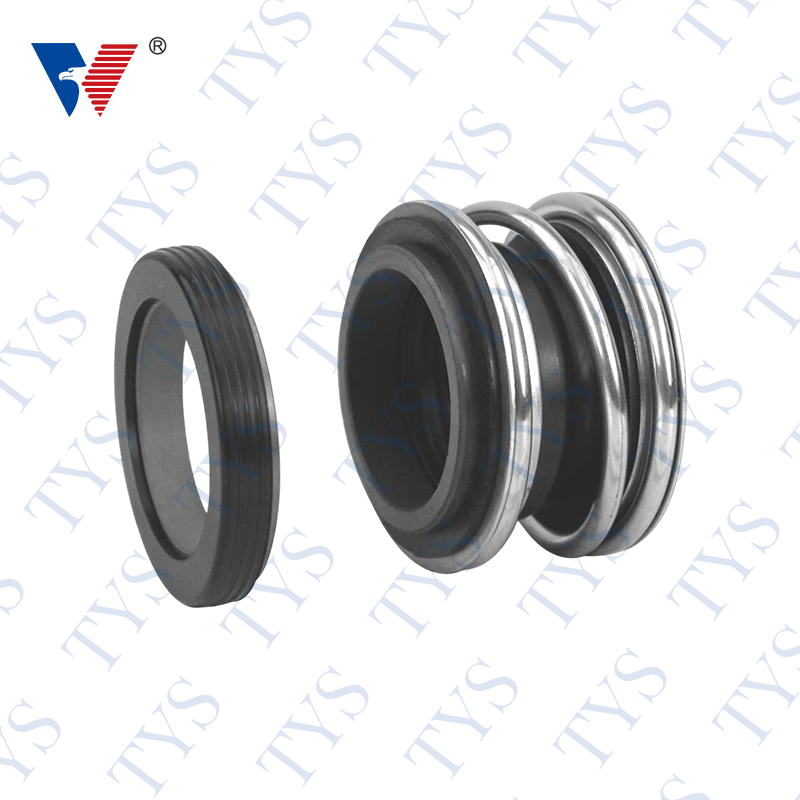

Typically, a vertical pump seal consists of several parts. There is the primary seal, the rotary portion of the seal and the stationary seal. The primary seal is designed to prevent liquid leaking between the rotating and stationary areas of the pump. The rotary seal is usually held in place by set screws. The stationary seal is fixed and cooled by the process fluid. The stationary seal part may be sealed with a gasket or O ring. The rotary seal part is also typically sealed with an O ring.

Mechanical seals are available in different sizes and designs. The rotary portion of the seal is usually cooled by the fluid being pumped. If the fluid is vented to the atmosphere, a specialized barrier fluid may be used to cool the seal. However, if the process fluid is polymerized, a clogging orifice can occur.

When choosing a seal, it is important to choose one that can withstand a variety of different conditions. For instance, a seal that can handle out of perpendicular alignment due to manufacturing tolerances can reduce wear on the shaft. Similarly, a flexible boot made of Teflon can help prevent liquid leakage around the seal face. A seal with a high-point vent in the seal chamber is also recommended. A seal that has a high radial clearance is ideal for VTPs.

A rotary seal can be accessed by removing the impeller from the pump casing. This makes it possible to see the rotary seal parts. If the seal is lubricated, the fluid is pumped into the seal chamber and the coolant is recirculated from the pump discharge head to the seal. If the seal is not lubricated, a separate lubrication system may be required.

A rotary seal is a seal assembly that rotates as the shaft rotates. The rotary seal is typically held in place by a bolt or set screw. It is important to note that the rotary seal faces should be able to withstand a wide range of temperature and pressure. This is especially important if the seal is being used in an environment where the fluid is likely to be exposed to corrosive chemicals. If the seal is being used in an area where the temperature is high, a heat exchanger or a cooling system should be added.

When choosing a vertical pump seal, it is important to consider the pump's piping plan. The piping plan should include the proper size orifice. The size of the orifice should be calculated based on the flow-rate needed to provide the desired flush flow.

A specialized barrier fluid can be used to cool the pack box. This fluid may be delivered from an external source, or it can be supplied from a reservoir in the seal support system. A clogging orifice can be caused by the polymerizing process, so the correct piping plans must be in place to prevent this.

A packed gland is a braided material that is wrapped tightly around the shaft. A packed gland is an important part of a vertical pump seal. The gland will wear over time, but it will still be needed for the seal to perform properly. The packing must be cleaned before pumping is performed. A specialized barrier fluid can also be used to clean the pack box.

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)